Laminated Busbar is also called combined busbar, multi-layers busbar, bus system, busway. It’s used for high-efficient current transmission and distribution. Contrast with traditional naked copper bar and wire, laminated busbar is the highway of current.

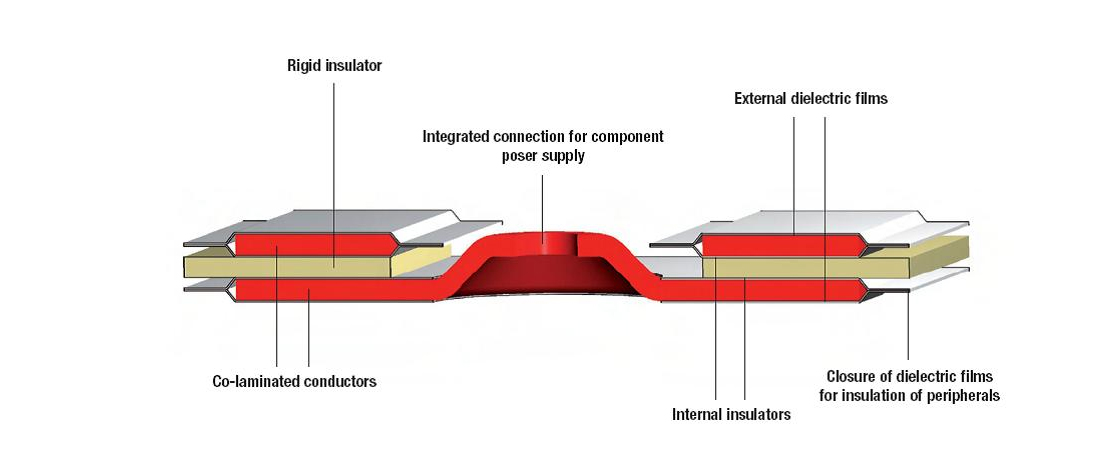

Product schematic diagram:

Current Power Laminated busbar advantage:

1.Lower inductance:The inductance is less than 20nh after designing improve;

2.Smaller space:Because the conductor is edge-sealed, other components and cabinet could contact with busbar directly. The space of the unit is reduce;

3.Wider application: CP busbars are used for various classes of voltage, example for 110V, 660V, 1140V, 3300V, etc;

4.Lower temperature rising: CP busbars are laminated by thin copper layers, which benefits heat distributing;

5.Lower cost:CP barbuars are designed easily assembling with IGBT and capacity, which reduces the assembly cost of engineers and works;

6.Perfect service: CP is continuously providing customers with value-added service, for example project design, process optimization, product test, system integration;

7.Enviromental protection: Raw material meets ROHS standard. Insulations meets UL94 inflaming retarding standard.

Product case:

Typical application parameters (actual parameters according to design requirements):

| Operating Voltage | 0-3300VAC |

| Operating Current | 0-1200A |

| Working Temperature | -40℃ +105℃-55℃ +125℃ |

| Conductance | <20nH |

| Working Life | >150,000H |

| Electricity Test | Voltage resistance, insulation resistance, partial discharge |

Material selection:

| Conductor | C1100 copper, A1060 aluminum |

| Insulation | PET、Nomex、Tedlar、Kapton、FR4、GPO |

All of the raw materials meet the demand of ROHS. Insulations reach UL requirements.