Extrusion + Horizontal Bending Busbar

Extrusion, also known as extrusion, is a plastic molding process, applicable to a variety of thermoplastic molding process. Extruded profiles are then formed into various types of busbars with different structures through the vertical bending process to meet the needs of electrical connections in various installation environments.

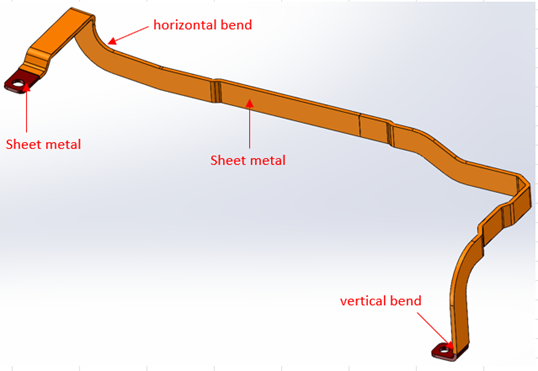

Product structure diagram:

Advantages of Extruded Vertical Bend Busbar:

1. Material utilization: Compared with the traditional stamping process, the material utilization rate of the vertical bending process can reach 98%.

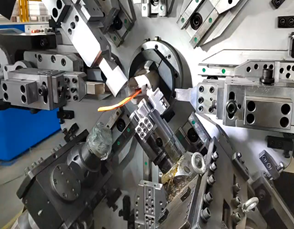

2. High degree of automation: the product adopts the same cross-section design, continuous extrusion molding, special vertical bending equipment, you can realize the whole automated production, high efficiency.

3. High product quality: continuous extrusion line with high-pressure testing equipment, thickness testing equipment, product quality monitoring at any time, high yield rate.

4. Product structure: the product can be freely adjusted according to the installation environment of the product bending structure, to adapt to a variety of shaped bending, vertical bending, horizontal bending, twisting and so on.

Product case:

Typical application parameters (actual parameters according to design requirements):

Operating Voltage | 0-3300VAC |

Operating Current | 0-800A |

Working Temperature | -40℃ +105℃-55℃ +125℃ |

Conductance | / |

Working Life | >150,000H |

Electricity Test | Voltage resistance, insulation resistance, |

Material selection:

Conductor | copper, aluminum |

Insulation | Nylon PA12 |

All of the raw materials meet the demand of ROHS. Insulations reach UL requirements.