The insulation material is adhering to the copper surface by special process. Powder coated busbar could pass voltage resistance tests around all of the surfaces of coating area. Supporting customer’s better engineering design possible, powder coated busbar could be different size and various shape. Also powder coated busbar could be laminated together.

CP powder coated busbar advantage:

1.Less temperature rise:The insulation of CP powder coated busbar is adhering to copper surface tightly. Comparing to traditional heat-shrinking-tube solution, powder coated busbar could distribute the heat through insulation directly, with less temperature rise.

2.Small space: CP powder coated busbar could be designed to different size and various shape, with outlet at any location, which save the assembly space.

3.Wider application:. The insulation of CP powder coated busbars are from 0.1-4.5mm, stand voltage resistance test from 0-35000VAC.

4.Strong adhesive: CP powder coated busbar could pass adhesion, impact, vibration, high-low temperature and others rigorous tests.

5.Perfect service: CP is continuously providing customers with value-added service, for example project design, process optimization, product test, system integration.

6.Enviromental protection: Raw material meets ROHS standard. Insulations meets UL94 inflaming retarding standard.

Typical application data:

| Working Voltage | 0-3300VAC |

| Test Voltage | 0-35000VAC |

| Operating Current | 0-1200A |

| Ultimate Temperature | -55℃ +125℃ |

| Working Life | >150,000H |

| Color | Green, blue, black, orange,red |

| Electricity Test | Voltage resistance, insulation resistance, partial discharge |

Material selection:

| Conductor | C1100 copper, A1060 aluminum |

| Insulation | Insulated Resin |

Actual data is based on the project’s demand.

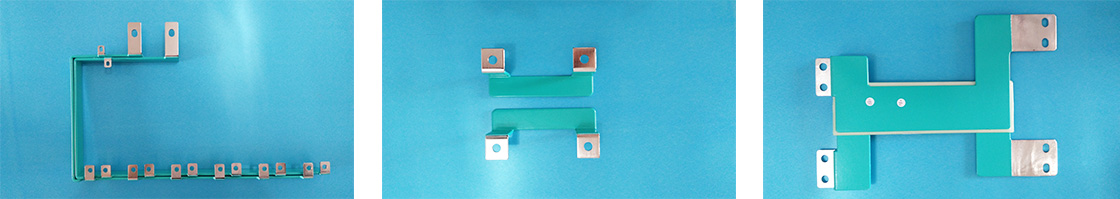

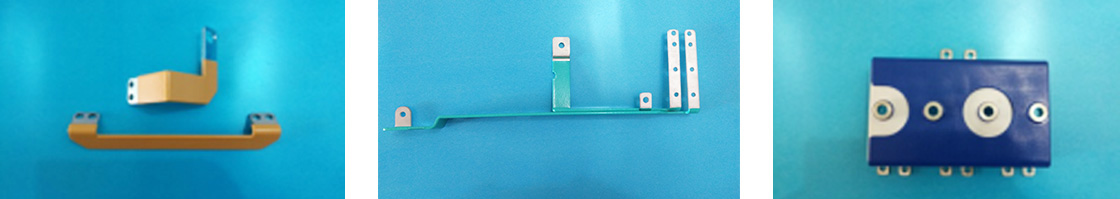

Product case: