CCS Introduction

CCS (Cells Contact System) integrated busbar, also known as battery cover assembly, is a module that integrates the conductive rows, control circuits (voltage and temperature acquisition) and other components of the battery module into one module to realize the high-voltage series-parallel connection of the cells, as well as the temperature sampling of the battery, cell voltage sampling, and over-current fusing, and to provide the temperature and voltage to the BMS system through the FPC, PCB, etc. and the connector components to the BMS system, which is part of the BMS system.

CCS integrated busbar advantages:

1. Simple production and processing, high degree of automation, saving assembly labor costs, avoiding the tediousness of too many connections in the wiring harness.

2. One-piece hot press molding, line sealing, oxidation resistance, corrosion resistance, high reliability;

3. FPC/PCB lines have over-current protection design to protect the battery cell, high safety performance;

Product Type:

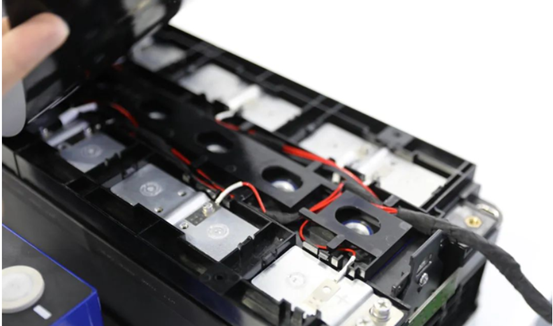

Wire Harness - CCS

Common structure: wire harness + collection terminals + NTC + conductive aluminum row + injection / blister bracket

Features:

✔ Integrated structure, mature technology

✔ Signal transmission is stable and reliable, voltage and temperature acquisition are connected by independent wire harnesses

✔ Cost advantage

✔ Lower degree of automation

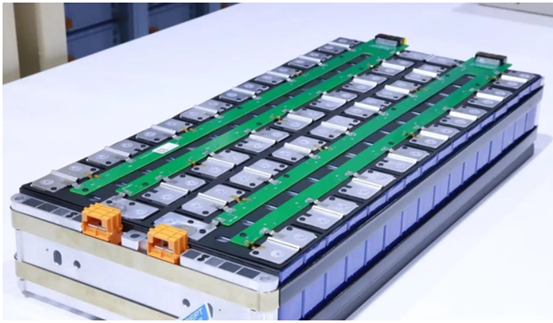

PCB-CCS

Common structure: PCB+Nickel sheet+Conductive Aluminum row+Plastic riveting or PET film hot pressing

Features:

✔ One-piece integrated structure, lightweight products

✔ Signal transmission is stable and reliable, voltage and temperature acquisition is realized by one-piece design PCB

✔ High degree of automation

FPC-CCS

Common structure: FPC + nickel sheet + conductive aluminum row + blister plate or PET film hot pressing

Features:

✔ Ultra-lightweight structure, excellent overall strength and insulation performance

✔ Stable and reliable signal transmission, voltage and temperature acquisition is realized by FPC with integrated design

✔ High degree of automation

✔ Relatively high cost

FFC-CCS

Common structure: FFC+Nickel sheet+Conductive Aluminum row+Suction molding hot riveting or PET film hot pressing

Features:

✔ Lightweight structure for long module acquisition design and cost reduction

✔ Excellent signal acquisition capability, stable and reliable signal output High degree of automation

✔ High degree of automation

The trend of integrated busbar CCS development toward high precision, high integration and intelligence to meet the needs of complex systems and variable applications. In the future, CCS technology will further realize miniaturization, high efficiency and reliability enhancement, becoming an important choice for more fields.